Anti-UV,Also Anti-fake

Last weekend, I talked a lot with my old friend Jane in a coffee shop about life, career, environment as we are always free to talk anything. Finally, when we spoke of our industry, he shared a secret with me which I regard as a common phenomenon, many manufacturers are now playing games with customers about anti-UV because they are trying to producing fake anti-fake productions but also avoid inspection by related department. How to do that? Let’s see.

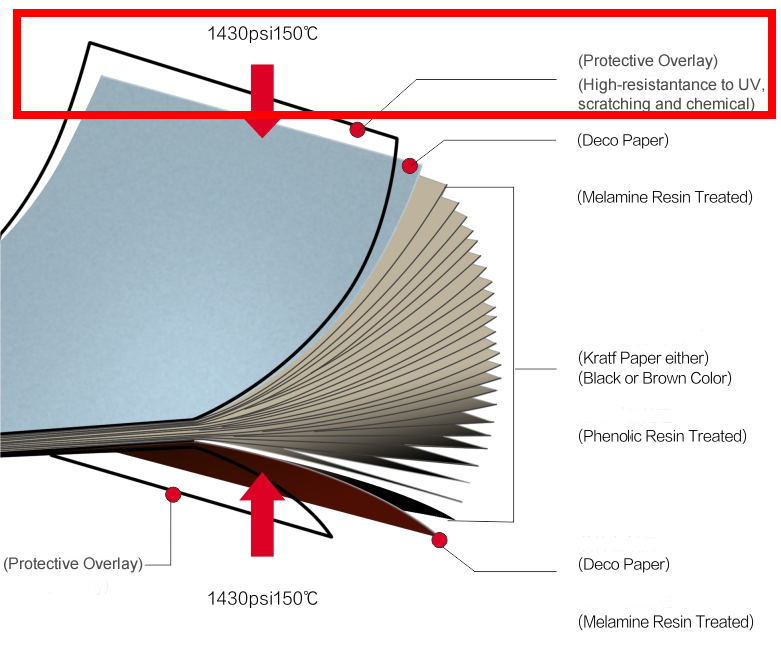

First of all, the attribute of anti-UV is widely used in the outdoor furniture, glasses, skin care product, umbrella and so on. Actually, it is an issue mainly about anti-UV layer which is mainly prevent from UVA and UVB. Or more specific, we could call it UV coating, a protective overlay normally processed at the outermost among so many coating.

I am not gonna explain how it could prevent from UV and any issue about chemistry, all I wanna tell you is that a machine producing anti-UV coating is extremely expensive which primarily causes the fake or low-quality anti-UV products just as a most common approach earning more money even for some big international enterprises. Without exaggeration, it has been a “open secret” in some specific industry.

However,how could it avoid inspection? It may be overstated by me, but as I noticed,two main process cause it. For one, reduction of anti-UV protective overlay.It is so easy to understand while the result is that the lifetime of fake anti-UV products will be reduced for several years without discovery. Secondly, mix the special UV coating with other materials when production. It is bitterly a bad behavior which will seriously effect the properties of anti-UV in practical application but meanwhile production steps and less cost.

Even so, what is the direct influence as for products? Obviously, rapid aging of production is unavoidable.Known from my friend Jane, the rate could be double which means that a commercial table top should be lasted for 10 years or more,but now it will crack and fade in 5 years. For example,HPL cladding (exterior cladding system) should be lasted for more than 15 years in general although exposed in the sun usually but with fake material, many problems come up in 7 years. It is not simply about asset depreciation but commercial fraud, don’t you think so?

Just as many related industry, cheating on customers using advanced approach has increasingly been a common phenomenon.Among them, Jialifu could offer you a secure guarantee.HPL with adequate UV coating could resist UV properly, with proper maintenance, it could easily last for more than 15 years that widely used for restaurant table tops, cafe table tops, round restaurant tables , wall cladding systems (exterior cladding system,hpl cladding) and so on.

Anti-UV and anti-fake, let’s keep bright eyes and resist fake goods.For more,please visit http://solidphenolicboard.com/info/news_c0032

Or contact us via

http://solidphenolicboard.com/art/contact-us_a0029.html